Advanced Decolorization Solution for High-Strength Pharmaceutical Wastewater

Effective management of industrial process water represents a critical challenge in pharmaceutical manufacturing, where complex wastewater streams present unique environmental and operational hurdles. Without proper treatment, these effluents can significantly impact ecosystems and regulatory compliance.

Problem Analysis: Multi-Parameter Wastewater Complexity

Our client’s pharmaceutical effluent exhibited characteristics typical of high-strength industrial wastewater, featuring variable flow rates and a challenging contaminant profile including organic solvents, acids, alkalis, salts, and phosphates. The wastewater demonstrated elevated color intensity, high suspended solids (5,000–23,000mg/L), significant ammonia nitrogen concentrations, strong odor, and substantial organic loading with low biodegradability—creating a multifaceted treatment challenge.

Treatment Scale & Client Objectives

With an average daily inflow of 70 m³, the treatment system required optimization to address three primary requirements:

1. Achieve regulatory color compliance

2. Reduce secondary parameters including NH3-N/TP

3. Lower overall operational expenditure compared to existing chemical treatments

Technical Solution: Performance-Optimized Coagulation Chemistry

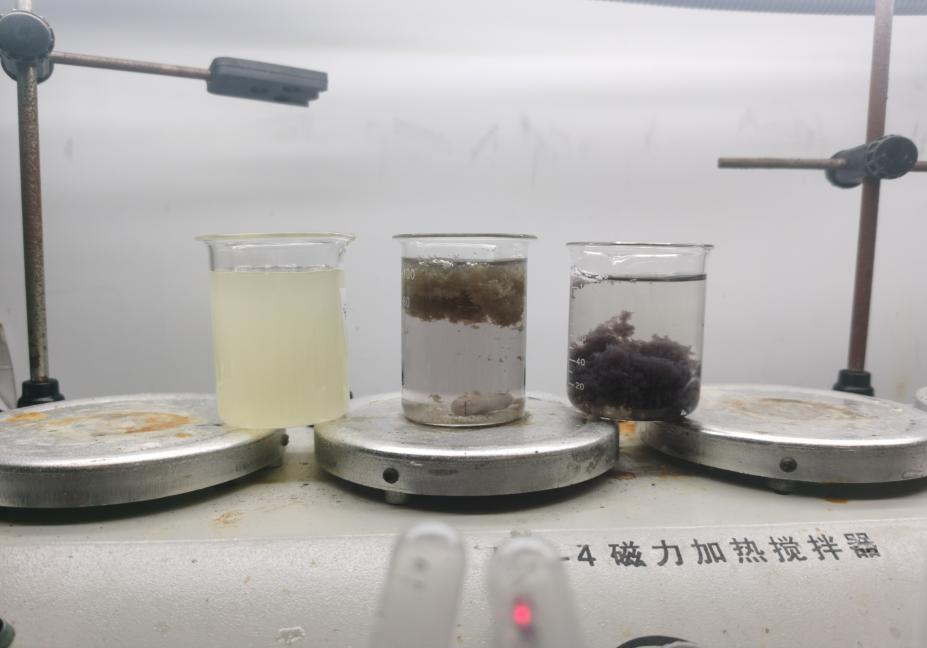

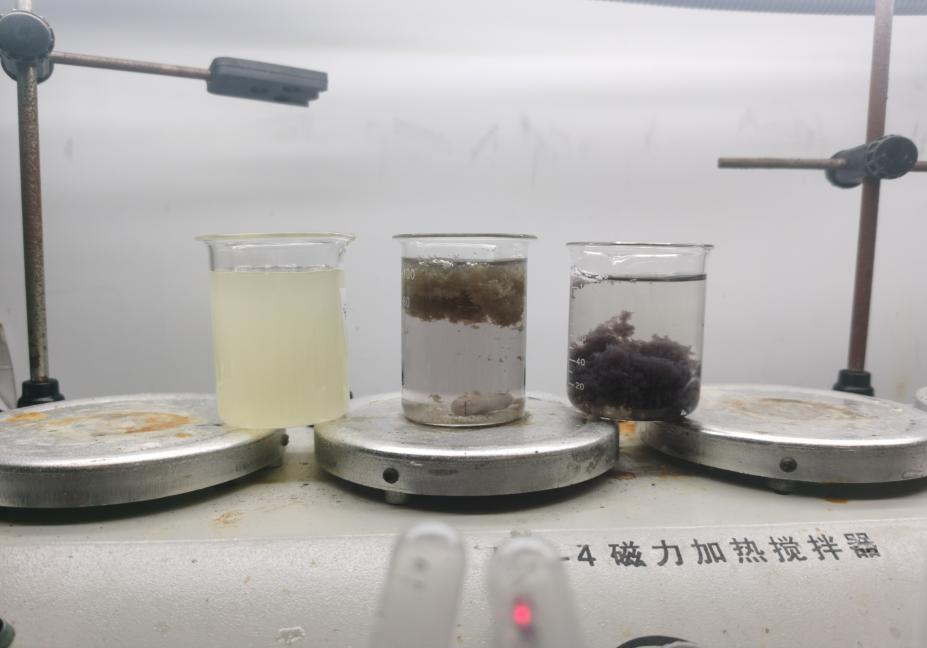

Our field engineers conducted comparative testing using the client’s actual wastewater (initial pH 4.2). We implemented a sequential treatment protocol beginning with 0.2% WaveClean decoloring agent, followed by pH adjustment using 0.6% 25% liquid alkali, and completed with 2% anionic PAM flocculant solution. Parallel testing with the client’s existing decolorant under identical conditions provided direct performance benchmarking.

Results: Enhanced Clarification & Parameter Reduction

Visual and analytical results demonstrated clear superiority of our WaveClean Decolorant. Treated samples achieved exceptional water clarity with reduced chemical dosage requirements compared to conventional alternatives. Post-treatment parameters included neutralized pH (7.2), COD 380 mg/L, NH₃-N 21.66 mg/L, and TP 1.6 mg/L—establishing optimal pretreatment for subsequent biological and membrane processes (DAF, anaerobic/aerobic reactors, MBR/NF) to achieve full discharge compliance.

Client Validation & Operational Impact

Full-scale implementation confirmed laboratory results, with the client reporting simultaneous achievement of color compliance, secondary parameter reduction (NH₃-N/TP), and measurable cost savings. The optimized chemical program additionally enhanced overall treatment plant efficiency through improved settling characteristics and reduced loading on downstream biological systems. Based on demonstrated performance, the client transitioned to our treatment protocol with immediate implementation.

This case validates that scientifically formulated specialty chemicals can transform challenging pharmaceutical wastewater treatment scenarios into opportunities for improved compliance, operational efficiency, and cost management within regulated industrial sectors.

As a professional chemicals manufacturer in the water treatment Industry, Sanmei have helped more than 5,000 plants with process solutions and helped them improve production efficiency, reduce costs, and optimize profit plans. Our main goal is to assist you in optimizing production efficiency and profitability in a sustainable way. Welcome to consult us and get a free wastewater treatment solution by filling in the form below or email to sales@san-mei.com.