In order to overcome the defects of surface hardness and wear resistance of aluminum and its alloys and extend the service life, it is necessary to anodize aluminum and its alloys to form an oxide film on the surface. This method is widely used in mechanical parts, aircraft and automobile parts, mobile phone shell, precision instruments and radio equipment, daily necessities and architectural decoration.

1. Case analysis

Today we come to a global fishing rod to do the largest enterprise, it is said that an ordinary fishing rod are thousands of dollars, everyone guess which company? The water quality of the dyeing wastewater is not stable due to the production process, and the plant has two kinds of wastewater (a dyeing wastewater and a wastewater containing heavy metals), which is undoubtedly a major challenge for the treatment of dyeing wastewater.

2.Difficult processing

Existing technology: reservoir -- dosing tank -- reaction tank -- sedimentation tank.

Currently in use: alkali tablets \ aluminum \ compound alkali \ polyacrylamide

Facing problems: oxidation workshop wastewater chroma is high, polishing wastewater phosphorus and nickel exceed the standard, the current agent is unable to meet the discharge standards.

3.Finial solution

Oxidation workshop wastewater dosing scheme:

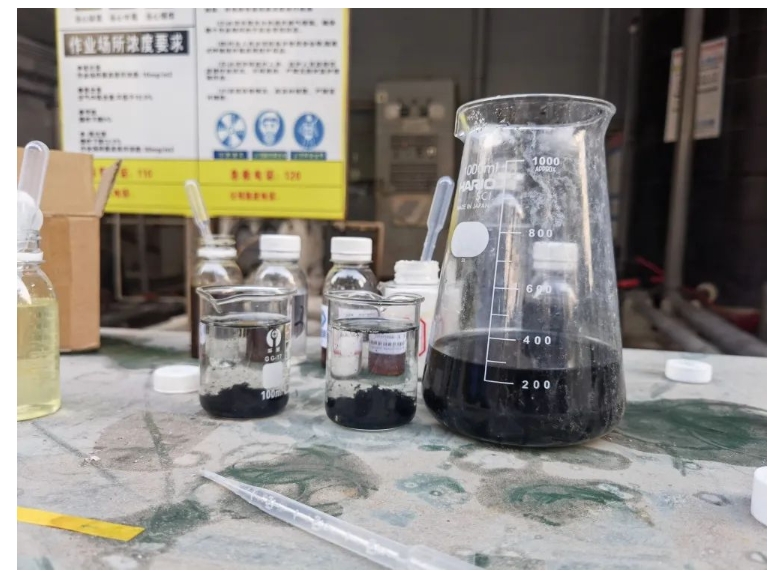

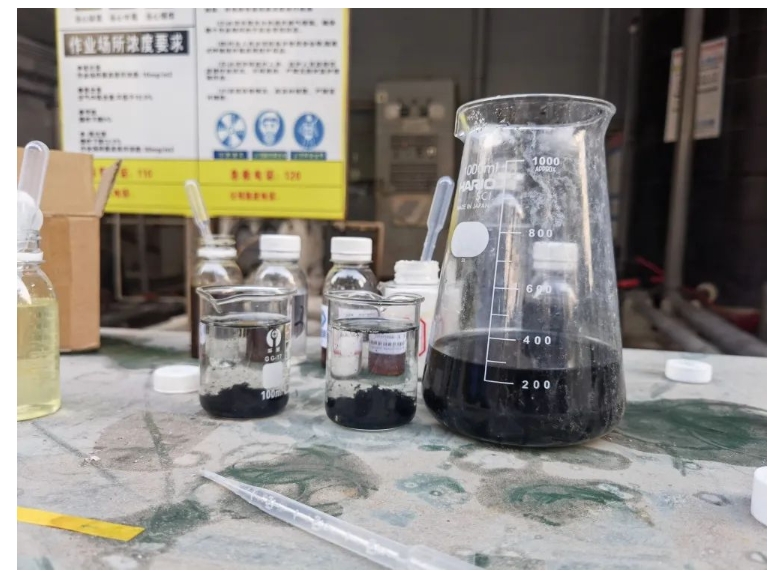

Decolorizing agent (1 ‰) -- -- -- -- -- adding PAC - adjust PH to about 7 -- -- -- -- -- -- to add PAM solution colour standard.

Polishing wastewater dephosphorization and nickel dosing program:

Heavy metal catcher (1‰) ----- Add PAC----- to adjust PH to 9-10---- add PAM to flocculate precipitation.

Treatment effect: effluent phosphorus reduced from 1200 to 0.1, nickel reduced from 22 to 0.1.