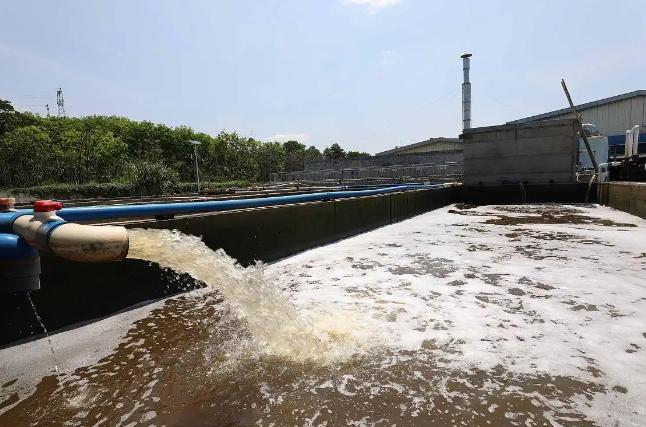

Mill Wastewater Paper mill wastewater originates mainly from pulping, bleaching, and papermaking processes. Pulping discharges dark-colored effluents containing lignin derivatives, hemicellulose breakdown products, and residual cooking chemicals. Bleaching stages, especially those using chlorine-based agents, generate organic pollutants like chlorolignins, which contribute significantly to water (colority). Papermaking processes add sizing agents, dyes, and fillers, further complicating the wastewater composition. These effluents are characterized by high (500-5000 Pt-Co units), COD (1000-5000 mg/L), and complex aromatic structures that resist biodegradation, making decolorization a critical treatment step.

-Coagulants/Flocculants: Aluminum sulfate (alum) and polyacrylamide (PAM) neutralize colloidal charges of chromophoric substances (e.g., lignin derivatives), causing particle aggregation for easy removal. Effective at neutral to alkaline pH, they remove 60%-80% of color but generate sludge and may require pH adjustment.

-Oxidants: Hydrogen peroxide (H₂O₂) combined with catalysts (Fenton's reagent) or ozone (O₃) break chromophore groups (e.g., quinones, azo bonds) through radical reactions, converting colored compounds into colorless small molecules. Suitable for refractory organic dyes, they achieve 70%-90% decolorization but are energy-intensive.

(2) Adsorptive Materials

-Activated Carbon: Its porous structure adsorbs dissolved organic colorants via van der Waals forces. High efficiency (80%-95% color removal) for low-concentration effluents, but regeneration costs and secondary pollution limit large-scale use.

-Nanomaterials (e.g., graphene oxide): Enhanced surface area and functional groups enable selective adsorption of aromatic dyes. Show promise for deep decolorization but face challenges in cost and recovery.

(3) Biological Agents

-Microbial Cultures: Fungi (e.g., Phanerochaete chrysosporium) secrete laccases and peroxidases to degrade lignin-related colorants through enzymatic oxidation. Mild reaction conditions and environmental friendliness make them suitable for low-to-medium wastewater, though slower reaction rates (24-48 hours) require longer retention times.

3. Targeted Treatment Strategies

For paper mill wastewater, a combined approach is often adopted:

-Primary Treatment: Use coagulation-flocculation (e.g., PAC + PAM) to remove 50%-70% of initial color and reduce suspended solids.

-Secondary Treatment: Employ biological processes (anaerobic-aerobic systems) to degrade biodegradable organics, complemented by oxidants (e.g., O₃) for residual chromophores.

-Tertiary Treatment: Apply activated carbon adsorption or membrane filtration for stringent discharge standards, achieving final <50 Pt-Co units.

Process optimization depends on wastewater characteristics: adjust pH to the optimal range (6-9 for coagulation, 3-5 for Fenton's reagent) and monitor organic load (COD/BOD ratio) to select cost-effective agents. Recent trends focus on developing composite decolorizers (e.g., magnetic chitosan nanoparticles) to enhance efficiency and recyclability, balancing environmental and economic sustainability.

WaveClean’s core mission is to empower industrial clients with profitable, eco-friendly wastewater management. Partner with us to access free, customized decolorization plans—simply fill out the form below or email info@san-mei.com for more information.