Today, with the booming pharmaceutical industry, pharmaceutical wastewater generated in a large number of production processes has become a major problem in the field of environmental protection due to its complex composition and high degree of pollution. These wastewater often have strong colors. For example, antibiotic production wastewater may appear dark brown, and synthetic drug wastewater is often dark yellow. These eye-catching colors are not only visual pollution, but also mean that the wastewater contains a large number of organic pollutants, heavy metal ions and other harmful substances that are difficult to degrade. If it is directly discharged without effective treatment, it will cause serious damage to the aquatic ecosystem and threaten the survival of animals and plants and human health. The pharmaceutical wastewater decolorizer is an effective weapon to deal with this problem.

The source of the color of pharmaceutical wastewater is extremely complex. On the one hand, the various raw materials, intermediates and products used in the pharmaceutical process themselves carry color groups. For example, many antibiotics contain chromophores such as conjugated double bonds and benzene rings in their molecular structures, which make the production wastewater appear in a specific color; on the other hand, in drug synthesis, fermentation and other processes, by-products produced by chemical reactions, residual catalysts, and acid-base reagents added to adjust the reaction conditions will also increase the chromaticity of the wastewater. In addition, microbial metabolites, proteins, pigments, etc. are also important factors that cause the color of wastewater to deepen. These complex color-causing substances are intertwined, making the decolorization of pharmaceutical wastewater a very challenging task.

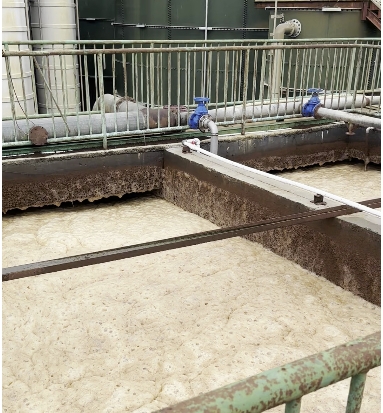

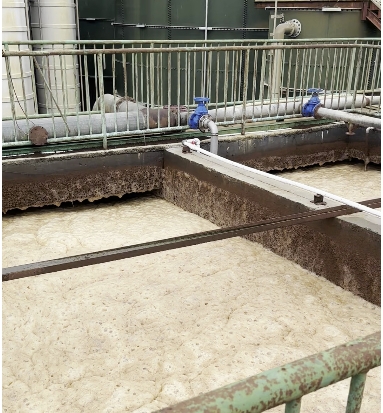

Chemical decolorizers play a core role in removing the color of pharmaceutical wastewater. According to the chemical composition and mechanism of action, chemical decolorizers can be divided into many types. Among them, flocculation decolorizers aggregate suspended particles and colloidal substances in wastewater to form large flocs through adsorption, bridging and netting, thereby settling and removing colored substances together. Common inorganic flocculants such as polyaluminum chloride (PAC) and polyferric sulfate (PFS) are widely used in pharmaceutical wastewater treatment. They can effectively reduce the turbidity and chromaticity of wastewater, and have good removal effects on hydrophobic dyes and some hydrophilic dyes. Organic polymer flocculants, such as polyacrylamide (PAM), further enhance the flocculation effect and improve the decolorization efficiency by virtue of their long-chain structure and strong adsorption capacity of polymer chains.

Oxidative decolorizers are another important type of chemical decolorizers. They use the oxidizing power of strong oxidants to destroy the chromogenic groups of color-causing substances in wastewater and convert them into colorless or light-colored small molecules. Common oxidants include ozone (O₃), hydrogen peroxide (H₂O₂), chlorine dioxide (ClO₂), and Fenton's reagent (Fe²⁺ + H₂O₂). Ozone has extremely strong oxidizing properties and can quickly oxidize a variety of organic pollutants and pigments. After the reaction, only oxygen is generated, and no secondary pollution will be generated; Fenton's reagent catalyzes the decomposition of hydrogen peroxide through ferrous ions to produce hydroxyl radicals (・OH). It has extremely strong oxidizing power and can oxidize almost all organic compounds. It is effective in removing difficult-to-degrade organic pigments in pharmaceutical wastewater.

Adsorption decolorizers rely on their huge specific surface area and rich pore structure to adsorb color-causing substances in wastewater on the surface, thereby achieving the purpose of decolorization. Activated carbon is the most commonly used adsorption decolorizer. It has good adsorption performance for various organic and inorganic pigments, and is especially suitable for treating low-concentration, high-chroma pharmaceutical wastewater. In addition, new adsorption materials such as diatomaceous earth, activated alumina, molecular sieves, etc., as well as modified adsorbents, are also being developed and applied. They show unique advantages in improving adsorption capacity, selectivity and regeneration performance.

Compared with other decolorization methods, chemical decolorizers have many significant advantages. First, chemical decolorizers have a wide range of applications and can effectively treat pharmaceutical wastewater of different types and components. Whether it is high-concentration or low-concentration colored wastewater, it can achieve the ideal decolorization effect by reasonably selecting decolorizers and optimizing treatment processes. Secondly, chemical decolorization has a fast reaction speed, and the decolorization process can generally be completed in a relatively short time, which greatly improves the efficiency of wastewater treatment. Furthermore, the operation is relatively simple, and does not require complex equipment and excessive technical requirements. It only needs to add the decolorizer to the wastewater in a certain proportion, and after appropriate stirring, reaction and separation operations, the decolorization and purification of the wastewater can be achieved. Moreover, with the continuous improvement of environmental protection requirements, new environmentally friendly chemical decolorizers continue to emerge, which can ensure efficient decolorization while minimizing the negative impact on the environment.

However, when using chemical decolorizers to treat pharmaceutical wastewater, some issues need to be paid attention to. Different types of pharmaceutical wastewater have different compositions, so it is necessary to select appropriate decolorizers and treatment processes according to the specific properties of the wastewater. If necessary, multiple decolorizers should be used in combination, or combined with other treatment methods such as biological treatment and physical treatment to achieve the best treatment effect. In addition, the dosage of chemical decolorizers needs to be strictly controlled. Too little dosage may lead to incomplete decolorization, while too much dosage will increase the treatment cost and may even introduce new pollutants. At the same time, by-products such as sludge produced by the use of chemical decolorizers also need to be properly handled to avoid secondary pollution.

With the continuous advancement of environmental protection technology and the increasingly stringent requirements for pharmaceutical wastewater treatment, the research and development and application of pharmaceutical wastewater decolorizers are also continuing to innovate and develop. In the future, new types of efficient, environmentally friendly and multifunctional chemical decolorizers will continue to emerge and, combined with advanced treatment processes, provide more powerful technical support for the deep treatment and resource utilization of pharmaceutical wastewater, helping the pharmaceutical industry achieve green and sustainable development.